Compressed Air Dryers

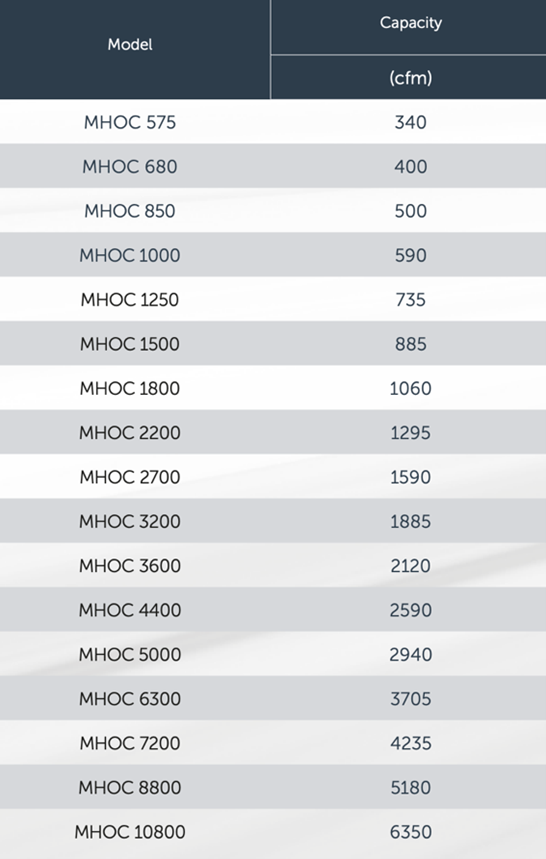

Mikropor MHOC Series – Heat of Compression Air Dryer

Energy-Efficient, Zero-Purge Compressed Air Drying

The Mikropor MHOC Series Heat of Compression (HOC) Air Dryer is an advanced, energy-saving solution engineered for use with oil-free compressors. Leveraging the natural heat generated during compression, this dryer operates without the need for external heaters or blowers, making it a zero-purge, pressure swing adsorption (PSA) system.

With its

twin-tower design, the MHOC Series efficiently removes water vapor from compressed air, ensuring reliable, consistent dry air output while maintaining the

highest energy efficiency in modern dryer technology.

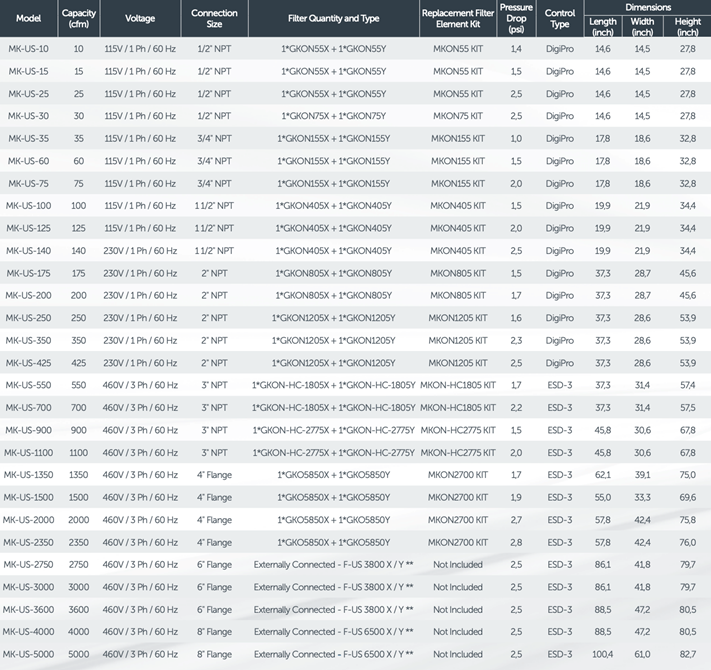

MK Series – Refrigerated Compressed Air Dryers

High Performance at a Cost-Effective Price

The Mikropor MK Series delivers best-in-class compressed air drying with unbeatable value. Engineered with a state-of-the-art heat exchanger and a high-efficiency refrigerant compressor, the MK Series ensures maximum energy savings and low operating costs—making it the smart choice for businesses seeking performance without the premium price.

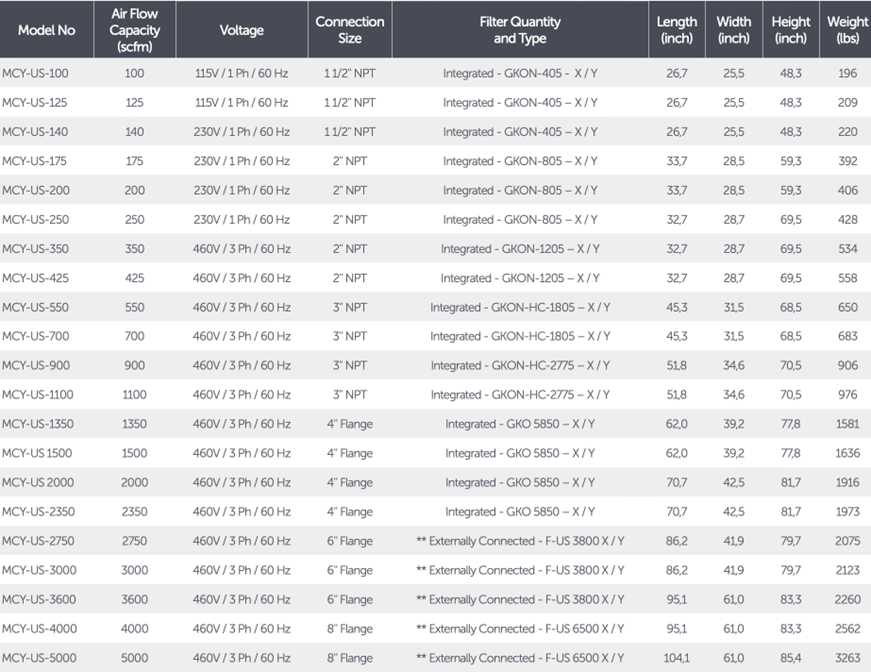

The MCY Series by Mikropor features cycling refrigerated air dryers that improve energy efficiency by using a unique cooling process. These dryers chill a special liquid and store it in a cold tank maintained at 34 °F. This pre-cooled liquid is then circulated through the system to cool down incoming compressed air, allowing moisture to condense and be removed.

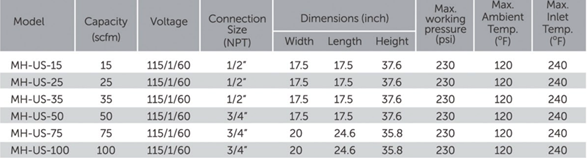

The MH Series by Mikropor is designed to address the challenges associated with high-temperature compressed air, particularly from piston-type compressors that typically do not include an aftercooler. As a result, the compressed air exiting these compressors can reach temperatures as high as 240 °F. Mikropor’s High Temperature Dryers in the MH Series come equipped with an integrated aftercooler that significantly reduces the inlet air temperature before it enters the dryer. This built-in feature ensures more efficient moisture removal, protects downstream equipment, and extends the life of the dryer system by preventing thermal overload.

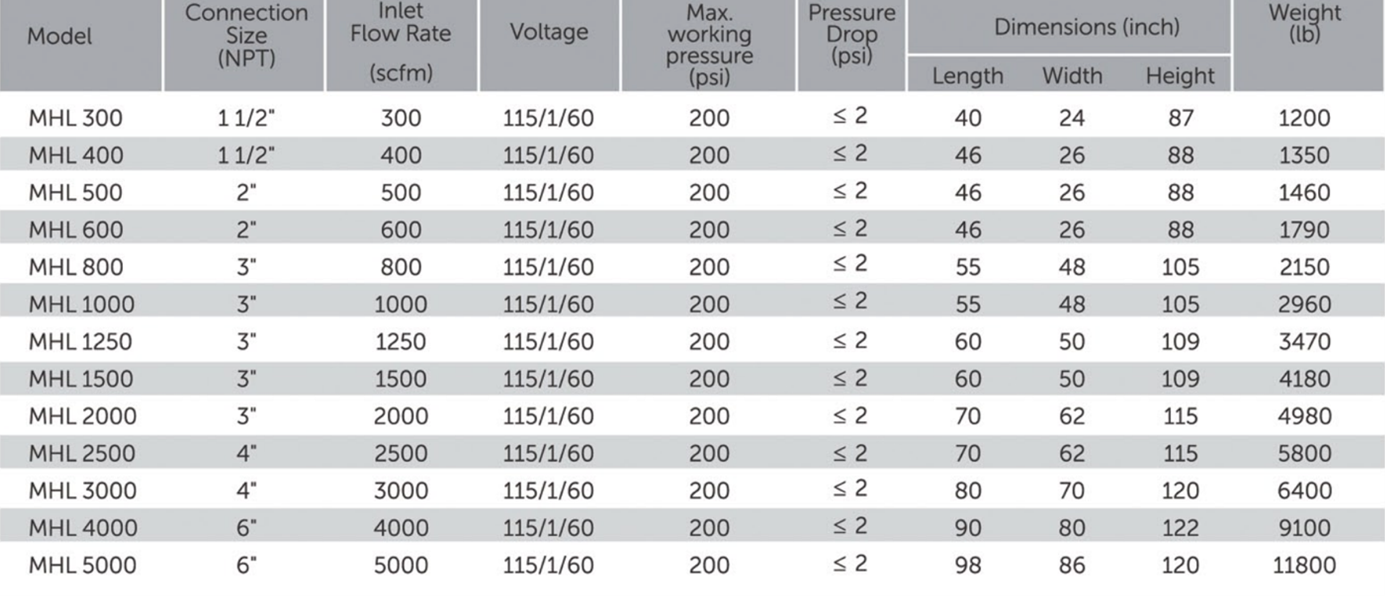

The MHL Series by Mikropor provides heatless desiccant air dryers with a constant -40 °F dew point, optionally down to -94 °F, ideal for critical applications. Each unit includes pre- and after-filters to ensure clean, dry air and protect the desiccant material.

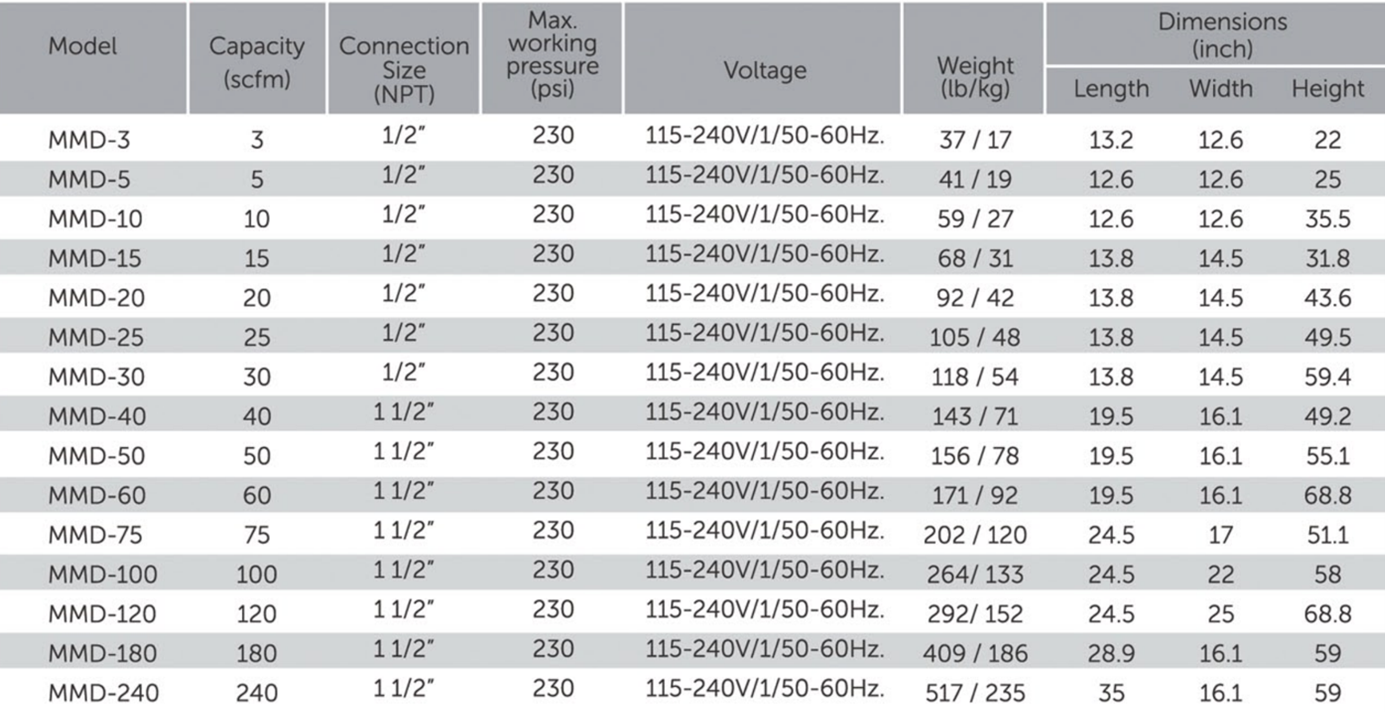

The MMD Series by Mikropor features lightweight, modular desiccant dryers that offer flexible installation and space-saving benefits. These dryers are less than half the size and weight of traditional twin-tower systems, making even the largest models easy to move through standard doorways. Designed for convenience and efficiency, the MMD Series provides high-quality compressed air wherever it’s needed.

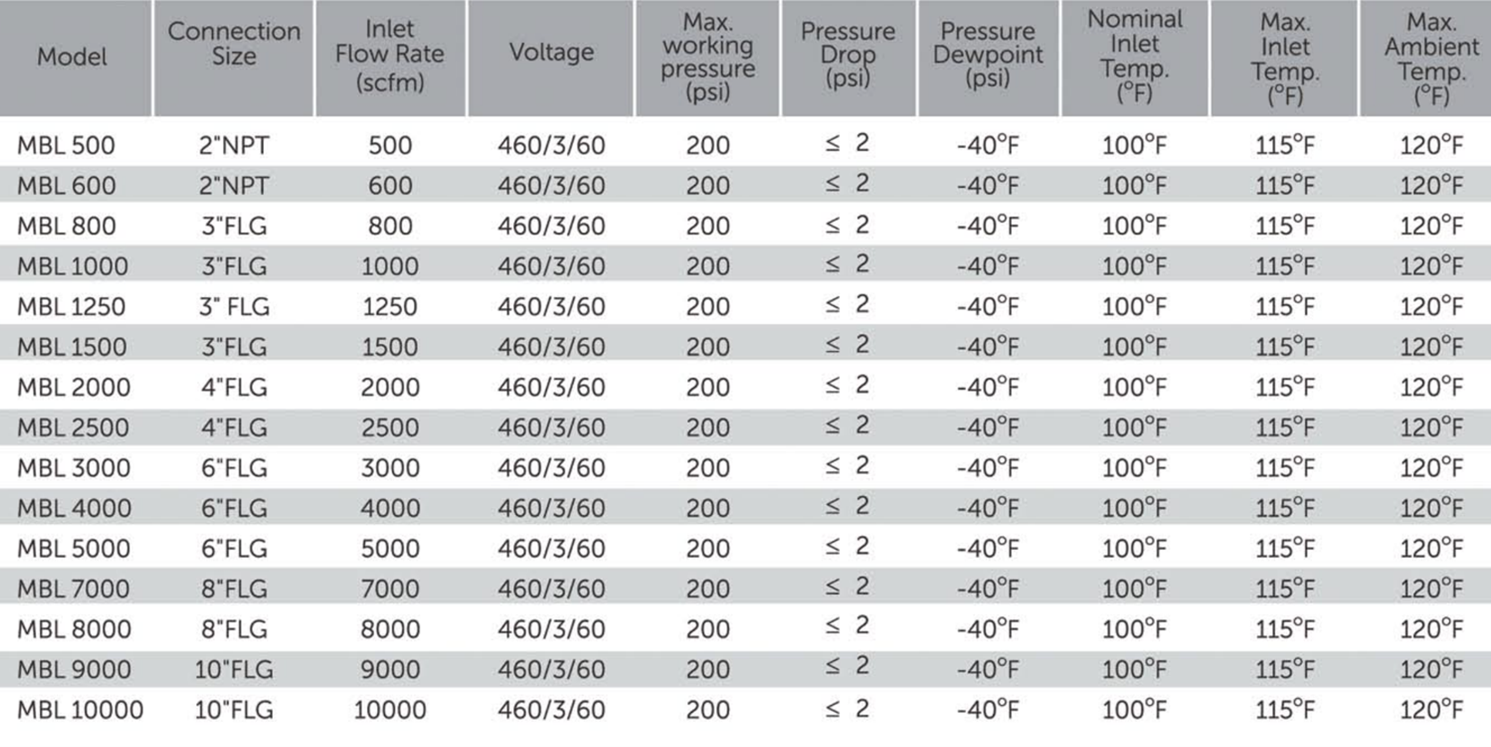

The MBL Series by Mikropor offers blower purge heated desiccant air dryers that maintain a constant -40 °F dew point with no purge air loss. Designed for energy efficiency and critical applications, these dryers include standard pre- and after-filters to ensure clean, dry air and protect the desiccant.

Compressed Air Filters

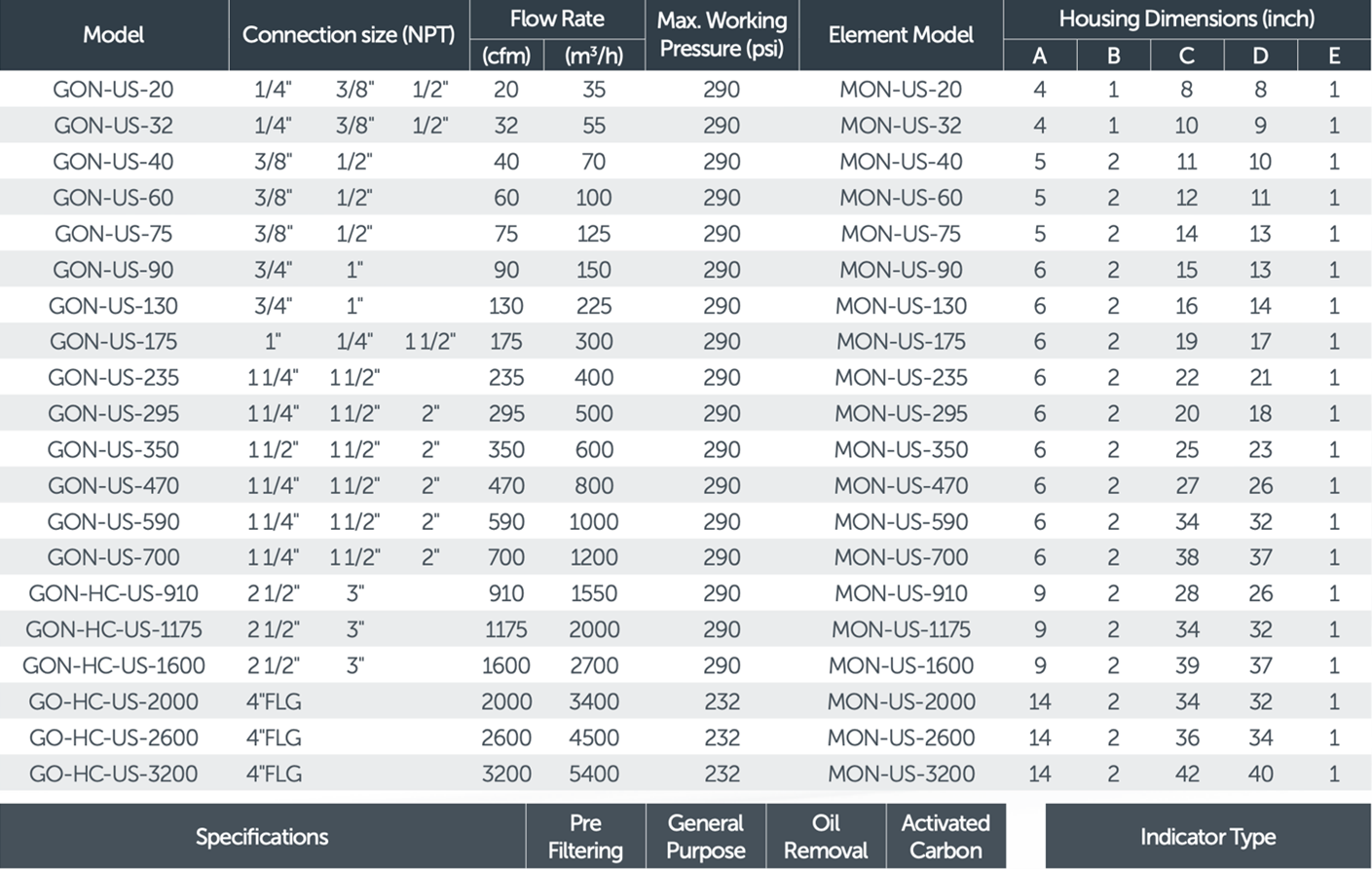

The GON Series by Mikropor is a new addition to the G and GO series, featuring compressed air filters designed for easy, “zero clearance” element replacement. This user-friendly design simplifies maintenance while ensuring reliable filtration performance.

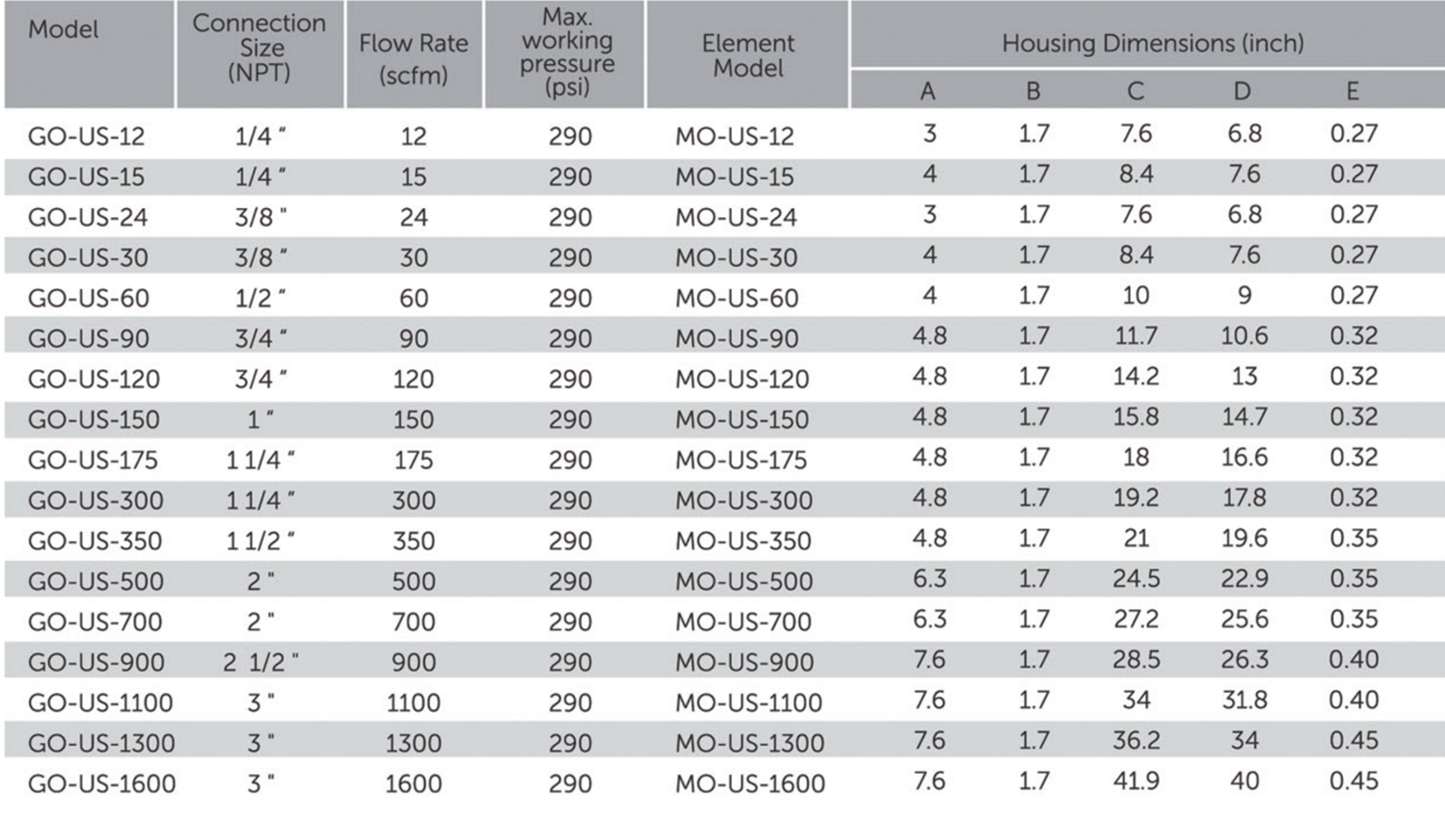

The GO Series by Mikropor is a new addition to the G Series, featuring compressed air filters with a “zero clearance” design for easy element replacement. This design enhances convenience and simplifies maintenance in tight spaces.

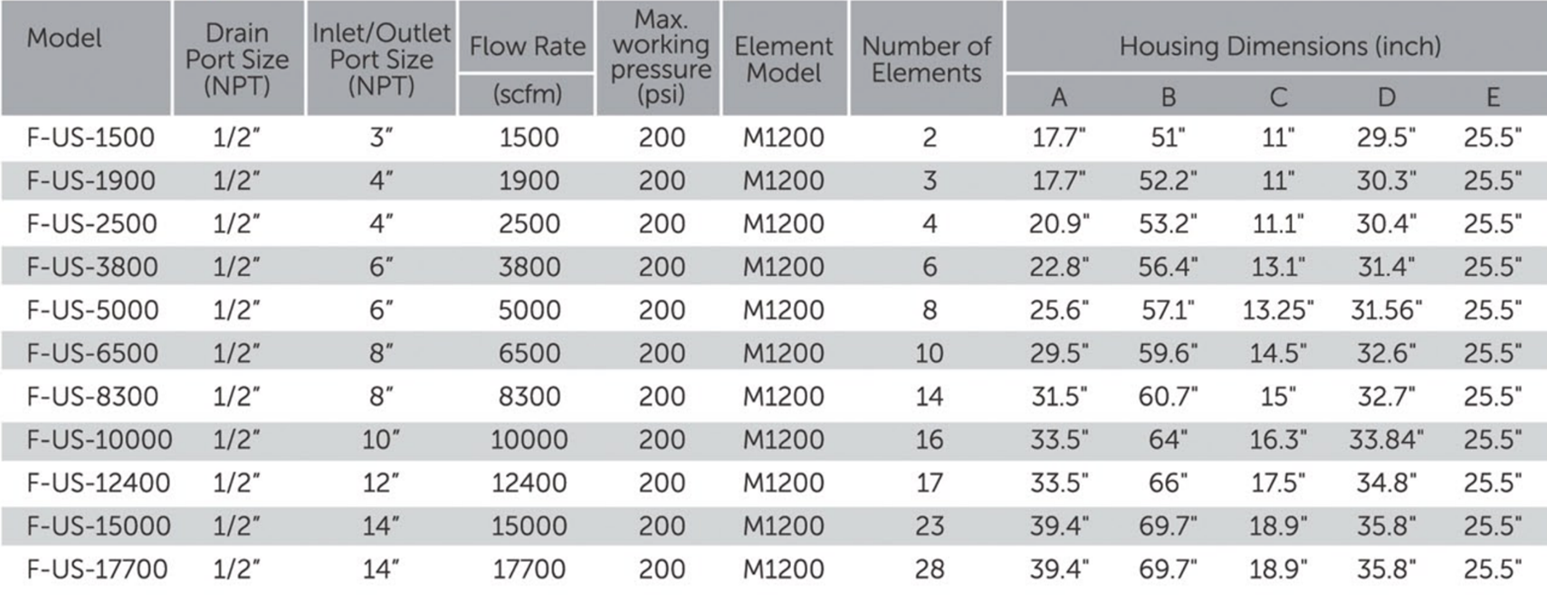

F Series

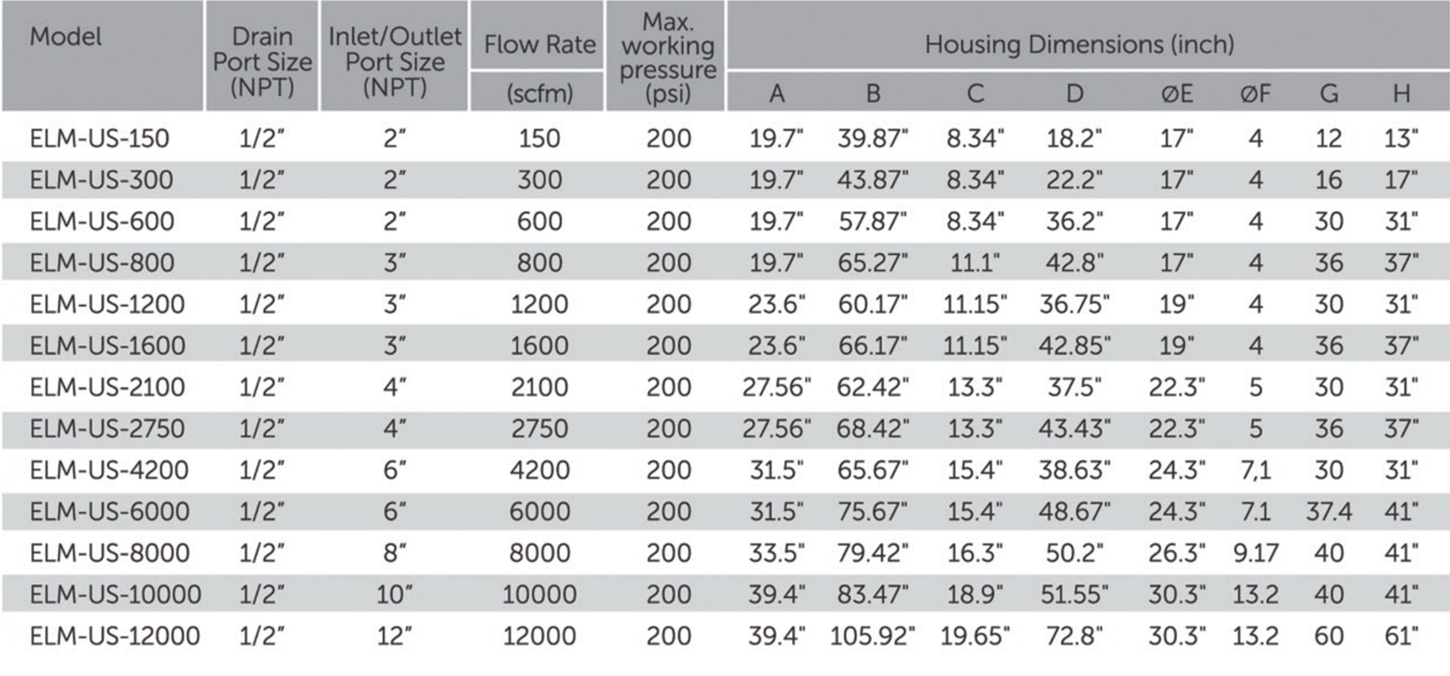

The ELM Series by Mikropor features Mist Eliminators designed for efficient removal of oil and mist carryover from piston or oil-flooded rotary compressors, ensuring cleaner, higher-quality compressed air.

The HG-HGH Series by Mikropor offers high-pressure solutions with two ranges: the 50 bar range made of aluminum for a strong, reliable, and weld-free design, and the 350 bar range made of steel, also featuring a no-welding design, ideal for high-pressure applications.